Correct installation of rack ceilings

When repairing a bathroom, the question arises: how to make a ceiling? There are several options: you can use a stretcher, plastic and plasterboard. Drywall is not the most suitable material for a room like a bathroom, because it can not withstand the long-term exposure to moist air.

The rack ceiling is made of plastic or aluminum rails.

There are, of course, moisture-resistant varieties of drywall, but in any case, drywall is less durable than the stretch cloth or plastic. One of the designs that can be used in the bathroom is the rack ceiling. To create it, plastic or aluminum slats are used. In addition, the installation of rack ceilings with their own hands is possible, which makes it possible to save money when repairing the bathroom.

Features

The main indicators that a material used to create a ceiling in the bathroom should have is the resistance to humid air and decorative properties. If the installation will be carried out by the owner of the apartment, then the ease of assembly is added to the two indicators. All these indicators and has a suspended ceiling rack.

Tools for installing a rake ceiling.

The stability of such an overhead structure to prolonged exposure to moist air depends entirely on the materials used in its creation. For the lath ceiling only materials that are not exposed to corrosion are used. Among such materials, aluminum, which has an additional decorative coating, and plastic (can be any color). All steel elements of the suspension device must be covered with a protective layer of zinc. Elements of this design do not swell and will not be covered with a layer of corrosion.

The decorative properties of the lath ceiling are high. The surface is produced in a fairly wide range of colors, so you can implement any design solution. In addition, modern technology allows you to apply on the slats of aluminum or plastic, various coatings that can simulate a large number of surfaces, for example, a wooden surface or the original pattern.

The ease of installation makes it possible to carry out this procedure to a person who does not possess any specific knowledge and does not have at his disposal special equipment. All materials used for this are light, so you can perform the installation alone.

Installation

In order to install the rack ceiling, as in the case of other suspension systems, it is necessary to pre-mark the plane with a special construction laser or hydraulic level. That is, the plane on which the frame of the structure will be located. Next you need to determine the height. This parameter is determined based on the depth of embedding of the built-in lighting devices, as well as the degree of curvature of the room's overlap. When marking, it is necessary to make a mark at a certain height from the floor surface on one of the walls, then transfer it to all corners of the room.

Elements of the design of the rack ceiling.

In order to subsequently facilitate their work, the previously placed labels should be joined together by a single solid line. You can make a similar line with the help of a thread. It is stretched between two previously marked marks, which are located on the same surface, after which it must be pulled and released. As a result, a smooth line will remain on the wall. Next, you need to repeat this procedure on all other walls of the room, which will be used when installing a ceiling design of this type. As a result, a plane will be identified, which will be used later in the installation of the ceiling structure.

Next, you need to attach a so-called wall corner to the wall surface. This element of the ceiling design performs decorative functions and is used to design the place where the slats adjoin the wall. The wall corner is a metal profile made of aluminum, made in the form of a corner, on which a decorative coating is applied. The wall corner is attached to the wall surface with the help of fasteners such as screws and dowels.

Types of suspended ceilings.

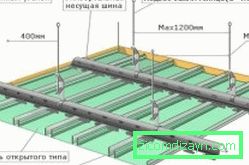

At the next stage of installation of a rack ceiling in a bathroom it is necessary to establish bearing elements. This work is not very difficult, because for its implementation it is enough to fix special suspensions on the surface, and then hang the load-bearing tires on them.

Only it is necessary to remember that from the longest walls the bearing tires should lag about 300 mm. It is to these tires that decorative panels are mounted.

Fastening of panels, rails made of strong aluminum or lighter plastic, it is necessary to begin with preliminary marking. Such a measure will avoid mistakes and rework in the future. Marking should occur in increments of 60 cm.

Reiki should be located parallel to the wall.

The process of marking is best started from the center of the ceiling surface. As a result of such a marking, a surface with parallel lines placed relative to each other should appear on the ceiling.

Work and nuances

Scheme of the installation of plastic roof panels on the ceiling.

After that on each of the received lines it is necessary to make marks which will be located on distance of 500 mm concerning each other. These markers are necessary for determining the places where they will be fastened with fasteners dowels. Such an element of the design of the lath ceiling, as a quick suspension, represents the spokes connected together by means of a special locking spring. One of the fast-spoke spokes ends with a loop, the purpose of which is to attach the suspension to the ceiling surface. The other spoke ends with a hook, which is used to hang the carrier bar. The main thing is that the quick-attachments should be installed strictly along a straight line. Only after fast attachments have been fixed, it is possible to cut the carrier tire and suspend it.

Now comes the final stage, namely the installation of plastic or aluminum panels. To fix the panels, the carrier busbars are equipped with special latches. During the installation of the rails, you only need to point the panel at them, and then snap it into place by fixing the rail directly. Also at this stage of installation, it is necessary to level the surface. In order to do this, it is necessary to loosen the hangers in the nearest row, so that the ceiling will drop a little and become even.

As you can see from the above, installation of the rack ceiling by one's own hands is a simple matter. It does not require any serious skills or complex equipment. The main thing is to be attentive while doing the work and use high-quality materials, then the ceiling will last a long time.