How to better level the floor with a self-leveling compound

When making the cladding works of the floor, the rough floor and the finish coat are distinguished. The first should be as smooth and smooth as possible. It is for him that there are jobs that are called screed or leveling. If it is with irregularities, then the final coating can crack, swell, deform. For example, tiles can crack, carpet or linoleum tear, parquet boards will pop up. The question is how to level the floor in the room. This problem is solved by the qualitative leveling of the rough surface with special mixtures.

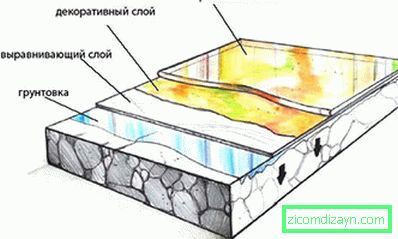

Scheme of the filling floor.

Distinguish the composition for leveling the rough surface, then the final coating and mixtures are laid on it, which themselves are leveled and become a finishing floor. The latter, as a rule, are intended for production, utility rooms, garages, workshops and the like.

How quickly to level the floor? The most effective among the materials used for the screed are self-leveling compounds. They form a thick heavy mass, which smoothly spreads along the plane, fills all irregularities, smooth or sharply delineated, cracks and other defects. As a result, a perfectly smooth and smooth horizontal surface is created.

In addition to the leveling effect, they have several other useful properties:

- very durable and durable surface;

- quickly dry;

- plasticity and safety in the ecological plan;

- ease of use: if you briefly describe the work, you need to prepare, apply and wait until it dries;

- resistance to high temperatures, fire, moisture;

- availability in a price ratio.

Components

Table of characteristics of leveling mixtures for floors.

They in their composition have quite traditional materials, such as cement (more often), gypsum. Quartz sand and limestone powder act as fillers. Depending on the kind of screed, the filler can be larger or smaller.

In addition to the above parts, there are also various plasticizers, special substances that retain moisture, give elasticity, promote creep and drying.

To apply such a composition, you need to prepare a foundation. There must be only a clean and solid plane, remove all pieces of small or large, cracked concrete. Garbage, glue, dust, stains of fat are removed. Cracks and holes cover and close up. In the end, the clean surface is treated with a primer. When large irregularities are detected, large differences in heights and holes are sealed with cement solutions or the same mixtures. The loose surface is primed twice. The substrate must be carefully prepared, otherwise it will lead to peeling and bloating of the material.

Mixing of the solution

The compositions are, as a rule, packed in bags of 25 kg. It's a powder. Be sure to read the instructions and consult the seller. The indicated amount is approximately 6-8 liters of water. There is a building drill with a nozzle, it will help to stir the solution, if this is not available, then a thick enough stick will do. Important is the rule: you need to pour the powder into the water, if it is done vice versa, then such a substance will be non-uniform. Do not dilute the already prepared solution, this will spoil it. Use it before you start to thicken.

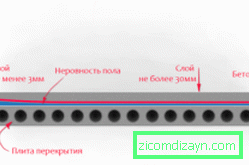

Scheme of leveling the floor with a self-leveling mixture.

It is ready for use in about half an hour after this. The work will have to be done quickly enough. Therefore, for large planes, break them into squares or areas, use beacons for this. The liquid must have a temperature of 10 ° C or more. Use a damper tape, it lies on the edges of the floor. The mixture pours to the surface and is applied with a spatula with denticles or simple steel.

There is a special roller with needles, they remove air bubbles from the surface of the coating, use it on a freshly-painted surface. The drying process is very short, you can walk on the floor after 4-5 hours. But for the final drying of the coating, you need to wait for about three, and maybe a little more than a day.

For liquid floors, this period is longer, they are dried very slowly, and it is completely ready in a month, although it also hardens quickly. During hardening it is desirable to protect the surface from dust, debris, water and similar substances, it can not be dyed and left, since without the final coating, it will simply become unusable.

Cover the polyethylene film with a surface when it hardens.

Kinds of compositions

There is a so-called rough equalizer, a rough self-leveling or thick-layered mixture. It is used for primary work on screeding and is suitable for parquet, laminate, linoleum, carpet.

There is a more universal finish equalizer. It can serve as an independent floor covering, which does not require final finishing or another coating. It can be painted, drawing on it various drawings, patterns, lines. These are thin-layer mixtures, they cover the surfaces after finishing.

Tools for installing the filler floor.

Sometimes the question arises, how to level the floor under the floor? There are special compounds for wood floors, they have fibers that improve their connection with wood. The fast-hardening mixture dries up just before your eyes, it is applied in a thin or thick layer. To give strength to the screed, sometimes its reinforcement is used.

Mixtures on which it is possible not to lay the finish coat are called filling floors. Their constituent part is a special kind of cement, alumina or portland, polymeric substances, pigments, dyes.

It is recommended to use if there are low ceilings in the room, it will save space, since the layer can be very thin.

Material selection

Consider several parameters when selecting materials:

- Purpose of the room. For example, if you need a floor that is very resistant to chemicals, easy to clean, resistant to various contaminants, mechanical influences, you can choose a composition that will be the finish coat at the same time. These are floors in industrial premises, in garages, chemical laboratories, warehouses.

- The level of humidity.

- Temperature regime.

- Base material (cement, concrete, plasterboard, wood).

- Loads.

As already mentioned above, there are compositions on a cement and gypsum basis. Cement plants are more stable, they will fit into rooms with any temperature regime and humidity. The layer of such a floor is from 5 to 50 mm. The mixture has a fast drying time (3-5 hours). It is more expensive than plaster. The latter, in connection with the presence in it of a component that is sensitive to moisture, is used in dry rooms. If moisture gets to such a screed, it becomes soft, deformed and loses its properties. Its thickness can reach 1 cm.

And finally:

- be sure to read the enclosed instruction, there is indicated all the necessary sequence and quantity of ingredients;

- before you level the floor, you need to prepare a foundation for it;

- It is necessary to wait from 20 minutes to 1 hour for the solution to spread well over the plane;

- if a large volume is poured, use a sufficiently large container to not then top up the missing quantity (it is unlikely that this can be done well, since the screed dries quickly);

- keep an eye on the room temperature, it should be from 5 to 25 ° C.

And remember, if the screed at least a little wet - do not finish the finish. It is better to wait a little longer, but be sure that it has dried well.